Custom Toroids: The Ultimate OEM & B2B Sourcing Guide 2026

Dec 16,2025 | nretec

In the world of precision electronics, "standard" often means "compromise." Whether you are designing a high-fidelity audio amplifier, a compact medical device, or a rugged industrial control system, off-the-shelf toroidal transformers frequently fall short. They might be slightly too tall for your 1U chassis, lack the precise secondary voltage you need, or fail to meet specific EMI requirements.

For OEMs and engineers unwilling to compromise on performance or form factor, custom toroids are not just an option—they are a necessity. Whether you need specialized toroidal power transformers for medical devices or precise toroidal coils for industrial filtering, custom solutions outperform standard off-the-shelf components.

At NRE, we understand that the transformer is the heart of your power supply. This guide explores the strategic advantages of custom toroidal transformers, the vast array of customization options available, and how we design to meet your exact specifications from prototype to mass production.

Table of Contents

1. Why Choose Custom Toroids Over Standard Laminated Transformers?

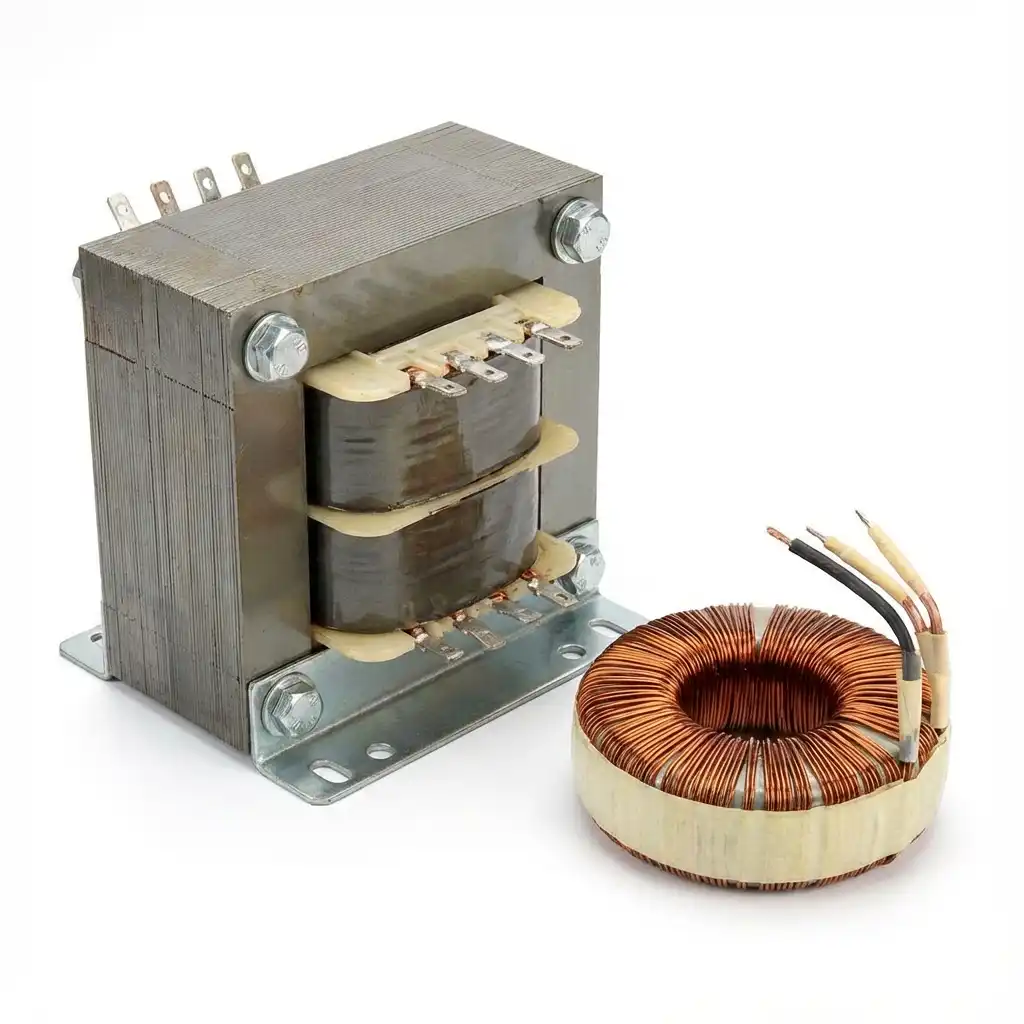

While standard laminated transformers (EI core) offer off-the-shelf convenience, they force your product design to adapt to their limitations. Custom toroids flip this dynamic, allowing the power component to adapt perfectly to your product requirements.

The inherent advantages of the toroidal geometry—a continuous ribbon of steel with no air gaps—provide superior efficiency and lower electromagnetic interference (EMI) compared to traditional laminated cores. See the comparison below:

| Feature | Standard Laminated (EI) | Custom Toroidal | Benefit of Custom Toroid |

|---|---|---|---|

| Core Structure | Air gaps present (E & I pieces) | Continuous wound strip (No air gaps) | Higher Efficiency (~90-95%), less heat |

| Magnetic Field | High stray field (EMI) | Constrained magnetic field | Ultra-Low Noise for sensitive audio/medical |

| Form Factor | Fixed, bulky cuboid | Flexible donut shape | Variable Dimensions (Flat/Tall) |

| Mechanical Hum | Prone to buzzing (loose laminations) | Silent (tightly wound core) | Acoustic Silence |

| Weight | Heavy | ~50% Lighter | Portable & Compact |

Space Optimization (The "Perfect Fit")

Standard transformers come in fixed dimensions. If your chassis has a height limit of 40mm but the standard 200VA transformer is 45mm tall, you have a problem.

Custom Solution: We can engineer a "Low Profile" custom toroid that flattens the geometry (e.g., wider diameter, lower height) to fit legally within your 40mm enclosure without sacrificing power rating. This flexibility is impossible with rigid laminated transformers.

Performance Tuning & Engineering Trade-offs

Standard units are generalists. Custom units are specialists. However, customization involves engineering trade-offs which our team helps you navigate:

- Lower Inrush Current: For medical or sensitive equipment, we can design the core and winding to minimize inrush current spikes.

Engineering Insight: Reducing inrush current typically requires lower flux density, which may increase the physical size of the transformer by 10-15%. We help you balance size vs. performance. - Ultra-Low Noise: For audio applications, we use high-grade Grain-Oriented Silicon Steel (GOSS) cores and lower the magnetic flux density to eliminate mechanical hum.

- Precise Voltages: Need 115V/230V input but with a non-standard 18.5V secondary? Custom winding delivers exactly what your circuit needs.

Simplified Assembly & Installation

Instead of standard flying leads that your team has to strip and crimp, a custom toroid can be delivered with connectors pre-installed (e.g., Molex, JST, TE connectivity) and leads cut to exact lengths. We can also integrate thermal switches or fuses directly into the transformer.

🚀 Need a Fast Quote?

Don't have time to read the full guide? Upload your specs or drawing directly to our engineering team.

Upload Specs for Quote »2. Customization Options: What Can NRE Customize?

At NRE, "custom" means you control every variable. Here is a breakdown of the specific parameters we tailor for our OEM partners.

⚡ Electrical Specifications

- Power Rating: From tiny 10VA signal transformers to massive 15kVA 3-phase power units.

- Voltages: Universal inputs, dual primaries, or industry-specific voltages (e.g., 480V). 5+ separate secondary windings possible.

- Frequency: Optimized for 50Hz, 60Hz, or 400Hz (Aerospace/Military).

📏 Physical & Mechanical

- Dimensions: Fully adjustable Outer Diameter (OD), Inside Diameter (ID), and Height (H).

Example: We have produced ultra-flat transformers (15mm height) for 1U server racks and tall-narrow units for columnar architectural lighting. - Mounting Styles: Standard Kit (Metal disk), Center Potted (Robust epoxy), PCB Mount, DIN Rail, or Encapsulated.

🛡️ Shielding, Protection & Advanced Processes

Beyond basic winding, we employ advanced manufacturing processes to ensure longevity and safety.

- Vacuum Pressure Impregnation (VPI): Unlike simple dipping, we use VPI to force varnish deep into the windings. This eliminates micro-vibrations and improves thermal conductivity.

- Electrostatic Shield (ESS): A copper shield between primary and secondary windings to attenuate high-frequency noise. Crucial for medical equipment complying with IEC 60601.

- Safety Standards: We design to meet UL 5085, UL 60601 (Medical), and EN 61558 standards.

3. The Custom Design Process at NRE: From Concept to Production

We understand that in product development, time is money. Our custom design workflow is built for speed and collaborative engineering.

- Consultation & Specification: Just tell us your application (Audio, Medical, Power Supply) and constraints.

- Engineering Proposal (1-2 Days): We analyze requirements and calculate core size/wire gauge. You get a datasheet and firm quote.

- Fast Prototyping (3-5 Days): We produce custom engineering samples quickly for your "smoke tests".

Note: We offer No MOQ (Minimum Order Quantity) for prototype runs. - Verification & Refining: We iterate quickly until the design is approved.

- Production & Quality Control: Manufacturing scales up (ISO 9001). Every unit undergoes rigorous testing (Hi-Pot, Resistance, No-load current).

4. Real-World Success Stories

Case Study 1: Protecting High-End Audio in Unstable Power Grids

Challenge: A luxury home theater integrator in Moscow faced voltage fluctuations threatening sensitive equipment.

Solution: NRE engineered heavy-duty Isolation Custom Toroids with massive core surplus and ESS shielding.

Result: "Black background" silence and verified surge protection for millions in equipment.

Case Study 2: Rapid Response for Defense Application

Challenge: A defense contractor needed a custom split-phase power fault detection unit in under 3 weeks.

Solution: NRE designed a custom assembly with sensors, relays, and indicators in a NEMA enclosure.

Result: Delivered in just 2.5 weeks, proving "custom" doesn't mean "slow."

Ready to Start Your Custom Project?

Don't let standard catalogs limit your innovation. Talk directly with our technical team today.

- ✅ Engineer-to-Engineer Support

- ✅ Low MOQ for Pilot Runs (10-50 units)

- ✅ Global Shipping (30+ countries)

Request a Custom Quote »