Dry Type Transformer: The Complete Guide 2026

Jan 24,2026 | nretec

Quick Answer:

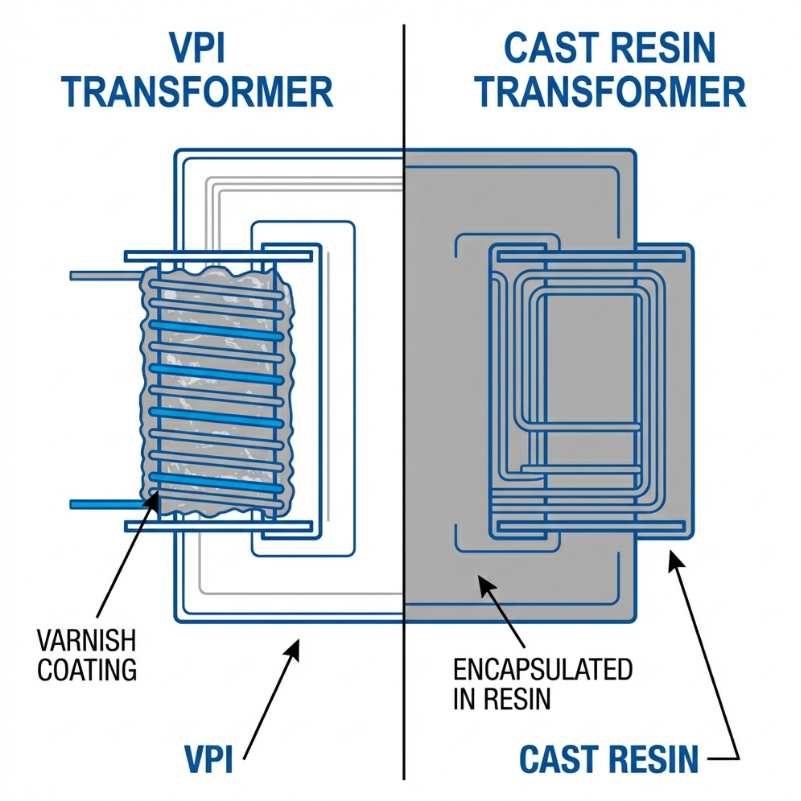

A dry type transformer is a transformer that uses air rather than liquid for cooling and insulation. Unlike oil-filled units, they are safer, fire-resistant, and virtually maintenance-free, making them the standard choice for indoor applications like shopping malls, hospitals, and high-rise buildings. The two most common technologies are VPI (Vacuum Pressure Impregnated) and Cast Resin (CRT).

Last week, a facility manager from a large commercial center in Manila called me in a panic. His 5-year-old dry type transformer had tripped due to overheating, shutting down half the building's AC units.

When our engineering team arrived, we found the issue wasn't the transformer itself—it was dust. The enclosure filters hadn't been cleaned since installation.

In my 15 years at the NRE factory, I've seen this happen too often. Dry type transformers are incredibly robust workhorses, but selecting the right type (VPI or Cast Resin) and understanding their maintenance needs is critical.

In this guide, I'll share everything you need to know to buy, install, and maintain the right dry type transformer for your project.

What is a Dry Type Transformer?

A dry type transformer is a magnetic device where the core and windings are not immersed in insulating oil. Instead, they are cooled by natural air circulation (AN) or forced air (AF).

How It Works

Just like any transformer, it transfers electrical energy between circuits through electromagnetic induction. The key difference lies in the insulation.

- In oil transformers, the oil acts as both a coolant and insulator.

- In dry type transformers, we use advanced solid insulation materials (like epoxy resin or varnish) and air channels to dissipate heat.

Factory Insight:

We are seeing a massive shift in the market. Ten years ago, 80% of our orders for industrial parks were oil-filled. Today, nearly 60% of new projects specify dry type transformers because insurance companies prefer their lower fire risk.

The 3 Main Types: VPI vs. Cast Resin vs. Open Wound

Not all dry transformers are built the same. At NRE, we manufacture the two dominant types: VPI and Cast Resin. Understanding the difference can save you thousands in long-term costs.

1. Vacuum Pressure Impregnated (VPI)

In VPI transformers, the coils are constructed with high-temperature insulation and then impregnated with polyester varnish under vacuum pressure.

- Pros: Lower initial cost, excellent heat dissipation, easier to repair.

- Cons: Less resistant to moisture and harsh chemicals compared to cast resin.

- Best For: General purpose indoor commercial and industrial environments.

- Availability: We offer both three-phase and single phase VPI units for lighting and control applications.

2. Cast Resin Transformer (CRT)

Also known as Epoxy Resin Transformers. The windings are completely encapsulated (cast) in epoxy resin under a vacuum.

- Pros: Virtually impervious to moisture, dust, and corrosive environments. High short-circuit strength.

- Cons: Higher cost, heavier, difficult to repair coils (usually replaced).

- Best For: Humid environments, hospitals, data centers, and heavy-duty industrial sites.

3. Open Wound

These are the basic "dip-and-bake" transformers.

- Pros: Cheapest.

- Cons: Lowest reliability. We generally do not recommend these for critical power applications.

Comparison Table: VPI vs. Cast Resin vs. Oil-Filled

| Feature | VPI (Dry Type) | Cast Resin (Dry Type) | Oil Immersed |

|---|---|---|---|

| Fire Safety | High (Self-extinguishing) | Excellent (Self-extinguishing) | Low (Flammable oil) |

| Moisture Resistance | Good | Excellent (Waterproof) | Excellent (Sealed tank) |

| Maintenance | Low (Dust cleaning) | Very Low | Moderate (Oil sampling) |

| Cost | Moderate | High | Low |

Key Specifications & Selection Guide

When you send us a Request for Quote, these are the 4 specs that matter most.

1. Power Rating (kVA)

Standard ratings range from 10 kVA to 2500 kVA.

- Tip: Don't size it exactly to your load. We recommend sizing for 70-80% continuous load to maximize efficiency and lifespan.

2. Cooling Classes: AN vs. AF

- AN (Air Natural): The transformer cools itself through natural convection. This is the base rating.

- AF (Air Forced): We add cooling fans to the enclosure.

Pro Tip: Adding fans can boost the transformer's capacity by 25% to 40%. Many clients buy a 2000 kVA unit with AF cooling to handle peak summer loads up to 2600 kVA.

3. Insulation Class & Temperature Rise

This determines how hot the transformer can run without failing.

| Insulation Class | Max Hot Spot Temp | Avg. Winding Temp Rise |

|---|---|---|

| Class B | 130°C | 80°C |

| Class F (Standard) | 155°C | 115°C |

| Class H | 180°C | 150°C |

Factory Advice: We recommend Class H insulation but designing for Class F temperature rise. This gives you a "thermal buffer" that extends the transformer's life significantly (based on Arrhenius equation).

4. Enclosure Rating (IP / NEMA)

- IP20 / NEMA 1: Finger-safe, protection against solid objects >12mm. Standard for indoor.

- IP23 / NEMA 3R: Protected against rain sprays usually up to 60 degrees from vertical. See NEMA Enclosure Types for details.

Applications: Why Indoor Matters

.png?w=798&h=807)

As shown above, dry type maintenance rooms are clean and oil-free, making them ideal for hospitals.

Conclusion

The dry type transformer is the safest choice for modern indoor power. Whether you choose VPI or Cast Resin, matching the specs to your environment is key.

Need a custom quote? At NRE, we've been building custom dry type transformers for over 30 years.

👉 Contact NRE Engineering Team for a free consultation today.

FAQ

What is the lifespan of a dry type transformer?

With proper maintenance, a high-quality dry type transformer from NRE will last 25 to 30 years.

Can dry type transformers be installed outdoors?

Generally, no. However, with a NEMA 3R weatherproof enclosure, they can be installed outdoors.